CNC Machines and CNC Machining Explained

CNC Machining Explained

CNC Machines are controlled by software allowing you to create designs easily and the machine to create the product, simple. However, digging deeper into the world of CNC it can get more complex. For example, a CNC machine can host a wide variety of different functions including routeing, milling, drilling and cutting which means they are incredibly versatile machines.

Machining Services CNC Benefits CNC History

The popularity of CNC machining has grown massively over the past few years. The popularity has grown as the need for manual labour is almost eliminated, meaning little need to employ, saving money from wages, along with the ability to repeat creations multiple times.

- The name CNC stands for Computer Numerical Control.

- CNC Machines are electro-powered devices that copy computer programming inputs.

- CNC represents just one of the two most common methods of machining.

- CNC Provides 3D printing to produce prototypes from a digital software file.

CNC MACHINING SERVICES

CNC Machines

Here at MNB Precision, we offer CNC machining services across the UK. We operate a wide variety of state-of-the-art CNC machines. Due to our broad capability and capacity, we are able to service industry leaders within the marketplace.

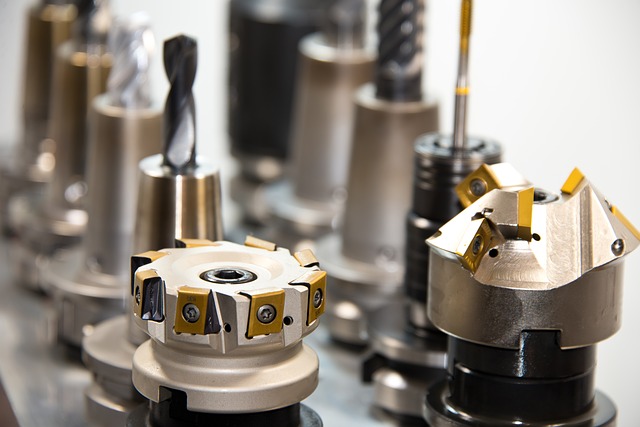

CNC stands for Computer Numerical Controlled, and it is the process used widely in all different types of manufacturing. These machines control tools such as lathes, mills and grinders.

Precision CNC Machining

When using CNC machining, the tools are being functioned through numerical control which can be customised for any project that includes both metal and plastic components. CNC Machines are efficient, fast and excellent at reducing material waste, which is why this is the most popular and accurate way of producing parts. It is a method used in modern machining to design components and a wide range of associated tasks.

There are plenty of advantages when using the process. Compared to manual machining the process is much more precise and can be repeated over again in exactly the same manner no matter how complex the initial design is. CNC Machines are used for the world’s most complex 3D shapes that need a high level of precision machining, and here at MNB Precision, our experts are fully qualified.

The process of the precision CNC machining service starts out with CAD drawings in both 2D and 3D with a code being created specifically for the CNC machine. When the program is loaded, a test run is performed to ensure everything runs smoothly. After the test is done, the process of creating the products can start and be repeated numerous times.

Different variations of CNC Machines

Just about every piece of metalwork equipment is available in a different type of CNC. Various types of CNC Machines include mills, lathes, EDM’s and Plasma Cutters to name just a few.

What are the benefits of CNC Machining?

Highly Accurate – The use of CAD creates extremely accurate drawings before the CNC process takes place.

Easily Repeat – Once there is a design or template created, it can be used multiple times to produce the exact same copy to precise specifications.

Cost effective – Our precision CNC Machining services are extremely accurate, so the waste material is kept to a minimum. The CNC machine also allows the user to take complete advantage of the raw materials.

Increases Production Speed – Parts that normally have to go through a number of steps before they can be completed, no longer have to go through such a lengthy process and so the process is much quicker using CNC Machines. The fully automated aspect means that the time of the overall production is cut down; the speed of production is significantly higher compared to other machining techniques.

Increases Levels of Safety – The CNC Machine operator is kept out of harm’s way as the whole process is automated, which makes it a much safer way to manufacture.

Very Efficient – CNC Machines feature an internal quality assurance detector, which makes the machines very efficient. As soon as a deficiency is detected the machine stops operating to prevent any material wastage.

A History of CNC Machines

- Known as NC when Computers weren’t around, the first form of NC machines were created in the 1950s and relied on punched tape as data storage. The initial concept proved cost effective however due to the fact it was different it took a while to catch on with most manufacturers. After the US Army bought NC machines and loaned them to different manufacturers, by the late 1950s NC machining started to catch on.

- The standard G-Code language began in the late 50s. G-Code is the generic name for a control language used in CNC.

- CAD came into CNC machining in the 60s replacing paper drawings at a rapid pace. Initially, CAD was more appropriate for the larger industry companies.

- During the 1970s the economy of western countries slowed down which meant employment costs increased. This meant that the need for CNC machines had increased and popularity started to grow in both large and small companies.

The CNC Machining Process

Although the world of CNC Machining can seem complex, the CNC Machining process itself is quite simple and our process involves the following steps:

- Design: Use CAD to create 2D or 3D models of the parts you need making.

- Programming: Use the CAM software to convert the CAD into G-Code, which is the language used to program these machines.

- Machine: Set up the machine with the correct tools and material.

- Make the part: When everything is set up, we can machine the part.

CNC Machines have been growing, becoming more and more advanced in recent years. Use MNB Precision for all of your CNC Machining needs; get in touch with our friendly and helpful team today. We cater to large project loads and smaller businesses.

Back to News