Shot Blasting

What Is Shot Blasting?

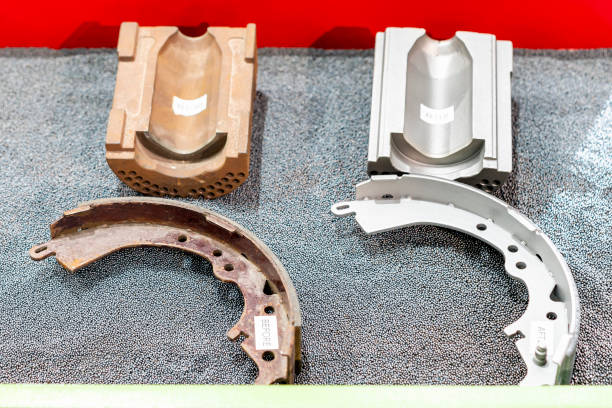

Shot blasting is an engineering method used to enhance the surface of various materials. It is similar to shot peening in that peening is used to strengthen metal but it can also be used to polish and clean. The blasting involves ‘shooting’ steel beads to clean the surface in an industrial manner. A turbine is used to propel the beads onto the desired surface. The ability to effectively remove substances such as oil, dirt, lubrication greases and other potential surface impurities is crucial in the long run. The potential problems such as uneven coatings and chemical substances mixing will cause adverse effects upon the efficiency and capability of surfaces.

How Does Shot Blasting Differ To Sand Blasting?

It is important not to confuse shot blasting with sand blasting. Sand blasting is similar but instead of shooting small metal beads sand is used. Both are used in a variety of industries including steel and aerospace. It is an extremely cost effective tool and practical way to extend the lifespan and performance of many crucial construction parts. Both sand and shot blasting are considered forms of abrasive blasting, which is a generic term coined for the process of smoothing and shaping a hard surface by firing solid particles at high speed at the desired surface. These two tend to be the most abrasive forms of blasting, firing either metal beads or sand. There are also milder forms of blasting such as glass bead blasting or ice blasting where less force is required.

Shot Blasting Considerations

There are many reasons why you should consider shot blasting when treating your materials. At MNB Precision we understand the importance of efficient and effective methods. It is therefore crucial that when products are created and installed they are free of fatigue cracks, corrosion, deteriorated strength and premature fatigue. That is why we highly recommend treating your materials. Below is a list of the benefits of blasting:

- It cleanses surfaces of non-friendly chemicals

- Provides a smooth polished surface that workers can also ensure is free of defects

- It increases longevity and durability of the steel relative to untreated materials

- Remove defections from the surface such as rust

- Effective and efficient speeding up the whole production process

MNB Precision – World Class Precision Engineering

These reasons ensure blasting is a staple in many industries when it comes to preparing surfaces. It is a safe, effective and efficient process that produces visible results instantly. This in turn allows a smoother and more efficient work flow benefiting everybody! If you require any shot peening or blasting services for your construction materials get in touch with MNB Precision Ltd today!