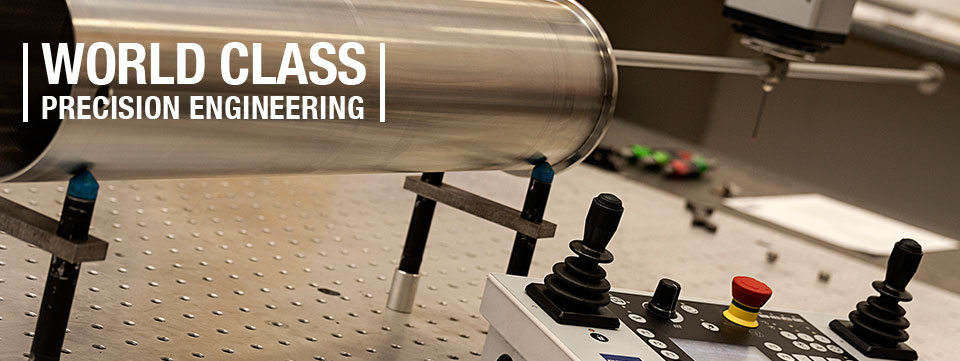

Coordinate Measuring Machines Inspections

What are CMM inspections?

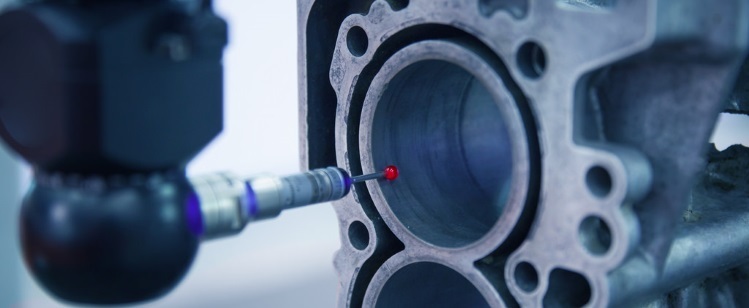

A CMM (coordinate measuring machine) inspection is where objects for products can be inspected for quality and measured. A Coordinate Measuring Machine is used to measure the dimensions and characteristics of an object. It can measure a single point in a 3D shape or the whole shape. CMM is made up of three axes X, Y and Z and each axis helps to measure the product as well as be able to position accurately in other precision machines.

Here at MNB Precision, our examination facilities allow us to inspect each product carefully which is critical when creating products and objects that need to be precision engineered. We examine samples small and large.

CMM Capabilities

The measurement capabilities of a CMM can stretch through many different parts such as:

- Dimensional – The ability to measure multiple axes of an object to get the whole dimension.

- Profile – CMM can capture profile information and the form of both 2D and 3D objects.

- Angle – Angles and orientation of two different points of an object can easily be measured.

- Depth – The ability to map the depth of any object with the use of two stereo images.

The Growing Need for Coordinate Measuring Machines

The need for CMMs and qualified precision engineers is growing which is why more intelligent devices have been coming into the industry over the past few years to keep up with the need for advancing functionalities. Coordinate Measuring Machines create effective and efficient manufacturing measurements.

Products can come in all shapes and sizes, so to measure each edge and dimension needs to be done accurately. As we create efficient technology parts are getting even smaller and over the years CMMs have catered to these tiny parts.

Here at MNB Precision, we have three different machines used for coordinate measuring and each machine is handled by fully qualified and skilled members of our team.

- Our Zeiss Accura can be used for most jobs as it has multiple sensor capabilities. The precision and performance are impeccable which are why most jobs will be used on this machine.

- Our IMS Impact is a British-built machine creating extremely accurate and fast measurements.

- Our Mitutoyo Euro 9166 uses temperature compensation systems that guarantee the accuracy of a high level.

If you would like any more information regarding our CMM inspection or any other precision engineering capabilities then get in touch with our friendly team here at MNB Precision today.

Back to News