Servitization helps precision engineering firm on road to market diversification

A family-run precision engineering business is passing on cost savings of up to 10% to all its customers, and has slashed lead times by 78%, after transitioning to a service based business model following work with the Aston Centre for Servitization Research and Practice (ACSRP).

MNB Precision Engineering recently celebrated its 35th anniversary. For much of that time, the company has carved a reputation for excellence in the oil and gas market, but following a huge decline in prices in this sector, and a wave of redundancies and cuts, the business was forced to look at other emerging markets for transferable services. A chance encounter with the Aston Centre for Servitization Research and Practice introduced MNB to the concept of servitization and showed its directors the opportunities it could open up for the company’s market diversification.

Managing Director of MNB Precision, Luke Benton, explains: “When Aston first presented us with the concept of servitization and the idea of transitioning our business model from a ‘make it-sell it’ mentality to a more service based model, we instantly started to see the longer term benefits that this could offer us. While the oil and gas market has always been, and will continue to be, one of our primary targets, it was important that we looked at evolving our business so we remain competitive and ahead of the times, not just keeping up with them. Aston helped us look at what we are actually offering our customers and how we could take this service offering one step further in order to build greater loyalty by adding value for our customers.”

Managing Director of MNB Precision, Luke Benton, explains: “When Aston first presented us with the concept of servitization and the idea of transitioning our business model from a ‘make it-sell it’ mentality to a more service based model, we instantly started to see the longer term benefits that this could offer us. While the oil and gas market has always been, and will continue to be, one of our primary targets, it was important that we looked at evolving our business so we remain competitive and ahead of the times, not just keeping up with them. Aston helped us look at what we are actually offering our customers and how we could take this service offering one step further in order to build greater loyalty by adding value for our customers.”

Servitization is the term that describes the change in model for a business, moving away from traditional product-orientated offerings, and more to a model where additional services are embraced, to supplement core products and services. The ACSRP is the world’s first and only centre dedicated entirely to understanding and promoting servitization within the global market. The 2016 Annual Manufacturing Report found that more and more businesses are starting to embrace servitization, with 41% already offering customer support agreements. Few businesses, however, are as far progressed with their servitization journey as MNB.

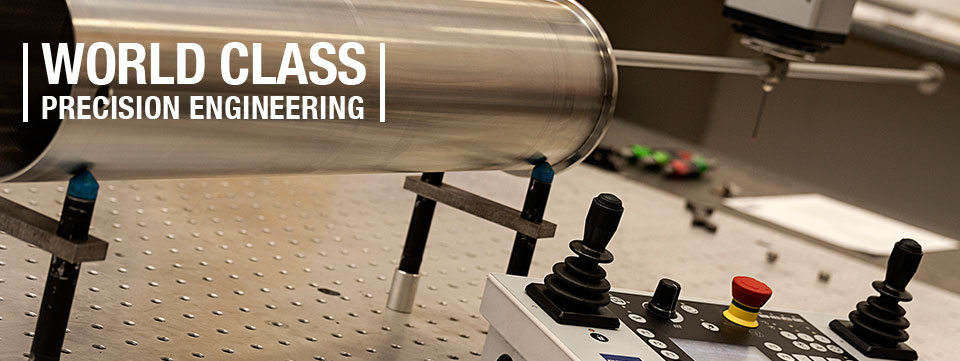

For MNB, servitization made the business look very closely at the services it currently provides to customers in order to ascertain how additional services can make them more effective. A specialist in CNC machining, jig boring, spark and wire erosion and grinding, MNB was already offering an impressive range of services to its customers. But in order to strengthen this further, the business identified some of the services it was having to outsource in order to bring a complete machining capability in-house, all under one roof.

Luke Benton takes up the story: “Although we already offered a wide range of services to our customers, we recognised that there were more services that we could bring in-house in order to reduce lead times for our customers and deliver a one-stop-service. For example, we previously had to outsource jobs for shot peening, magnetic particle inspection and liquid dye penetration, which was not only an incurred direct cost we could not recoup, but also meant that lead times for our customers were longer. An average lead time for a typical job used to be around 18 weeks, but by bringing additional services in-house and delivering a complete solution to our customers, the average lead time is now just four weeks.”

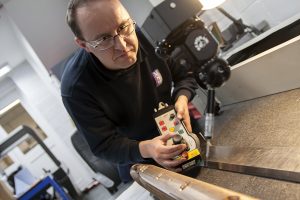

MNB invested in the right capital equipment and training in order to bring all of these services in-house. Rather than embark on an ambitious recruitment drive, the business looked to upskill its existing workforce with additional training in order to help them work to full capacity. As a consequence, the business has been able to create one of the UK’s most impressive and effective Non-Destructive Testing facilities and reduced both lead times and costs for customers.

MNB invested in the right capital equipment and training in order to bring all of these services in-house. Rather than embark on an ambitious recruitment drive, the business looked to upskill its existing workforce with additional training in order to help them work to full capacity. As a consequence, the business has been able to create one of the UK’s most impressive and effective Non-Destructive Testing facilities and reduced both lead times and costs for customers.

Bringing everything under one roof had further meaning for MNB. The business was previously working across three disparate sites, which caused a number of problems in regards to communication flow. The company is capable of machining parts up to 11 metres long, 1m in diameter but transporting these products from one site to another threw up a number of logistical issues, resulting in wasted time. As MNB started to bring all of its services under one roof, the business decided to take a literal approach as well, and re-located the entire premises into one single building, from which it could quickly and effectively facilitate jobs from start to end.

Luke Benton continues: “What we’ve noticed on our servitization journey, is that once you add up the small amounts of time we used to waste by outsourcing jobs, or transporting finished parts over public footpaths via forklift truck, it resulted in a huge overall amount of wasted time. By consolidating our services and our location, we have been able to make small improvements in efficiency that have led to greater improvements for our customers.

“Today, we are a lot more reactive to what our customers require and can deliver a wide range of services in smaller timescales and at a reduced cost, which is keeping us moving forward despite challenging market conditions, and enabling us to build a strong competitive advantage as well.”

By embarking on a journey of servitization, MNB has consequently been able to start to make the move into new markets to supplement its presence in the oil and gas market. For example, a number of RFQs from customers in the nuclear and defence sectors detail the process of machining a part, sending it away to be welded and then coming back again to be machined. As the business starts to look at bringing welding services in-house to support its shot peening and NDT services, the business will be able to make further moves into this sector.

For Luke Benton, although MNB has recorded some tangible results and benefits from servitization, the journey does not end here. Instead, he believes that servitization is more of a change of mindset than anything else and must be ingrained into a business if it is to continue to be successful.

“We are always looking for ways to continue to servitize our business model now. Aston’s support opened up our eyes to the idea of servitization and they helped us realise the benefits, and today it has become part of our culture. The next step for us is to continue our consolidation and start to explore our capacity for higher batch volumes, which includes looking at pallet loading machines. We’re also investigating welding services and ensuring that our team is continually taking advantage of training and new opportunities in order to remain engaged and focused on the wider goals of the company. Servitization is a long term process which requires a change of mindset for many manufacturers, but as we have experienced, it can produce some quick results.”

– Ends –

About MNB Precision

Established over 35 years ago, MNB Precision is a family run business based in Coventry, which provides manufacturing and precision engineering services to world leading companies across the oil and gas, power generation, rail, aerospace and other manufacturing industries. Specialising in precision engineering, the company’s 36,000 ft² factory offers services including CNC milling and turning, Jig Boring, Spark Erosion, Wire Erosion, Grinding and Shot Penning. These in house capabilities are supplemented with a robust and controlled supply chain, enabling the business to offer an efficient turnkey solution to customers globally.

For further information, please contact:

Luke Benton, Managing Director, MNB Precision on Tel: 02476 696950, or John Edden, Bridge PR & Media Services on Tel: 024 7652 0025, or Email: john@bridgepr.co.uk