Tolerance for precise engineering at Rail Live 2021

Visitors to this year’s Rail Live can gain an insight into how engineering practices from the oil and gas industry are enabling the production of rail safety-critical components machined to the highest tolerances.

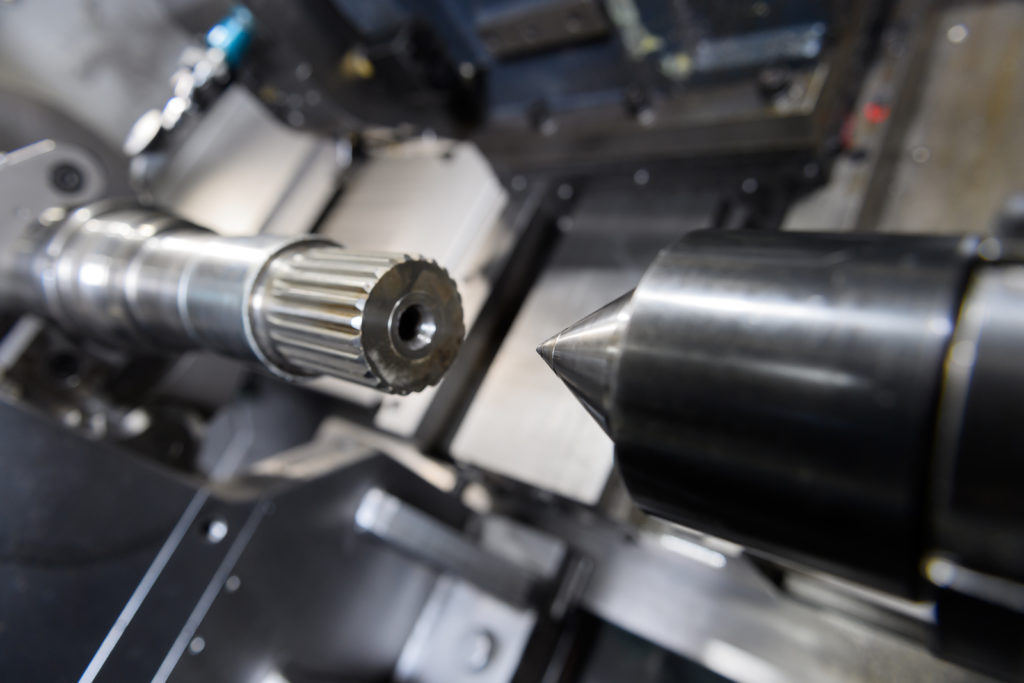

MNB Precision is supplying the rail sector with high-performance rail axles, shafts, and bearing housings machined to the highest tolerances using specialist engineering techniques and tools honed in the oil and gas sector – an industry where safety is quite literally the difference between life and death. As the rail sector continues to benefit from centralised investment in growth, such safety-critical components are in demand.

The company works extensively with rail and metro customers and has developed a deep understanding of the rail industry’s unique requirements. The complex nature of parts, in combination with tight tolerances and strict material properties, means the SME is well placed to support customers as they scale up operations. Furthermore, MNB’s work within the oil and gas market means it has a wealth of experience supplying robust and reliable parts for use in safety critical environments. Its manufacturing envelope is from 6mm to 1000mm diameter in turning and 1000mm x 1000mm x 10000mm cube in milling.

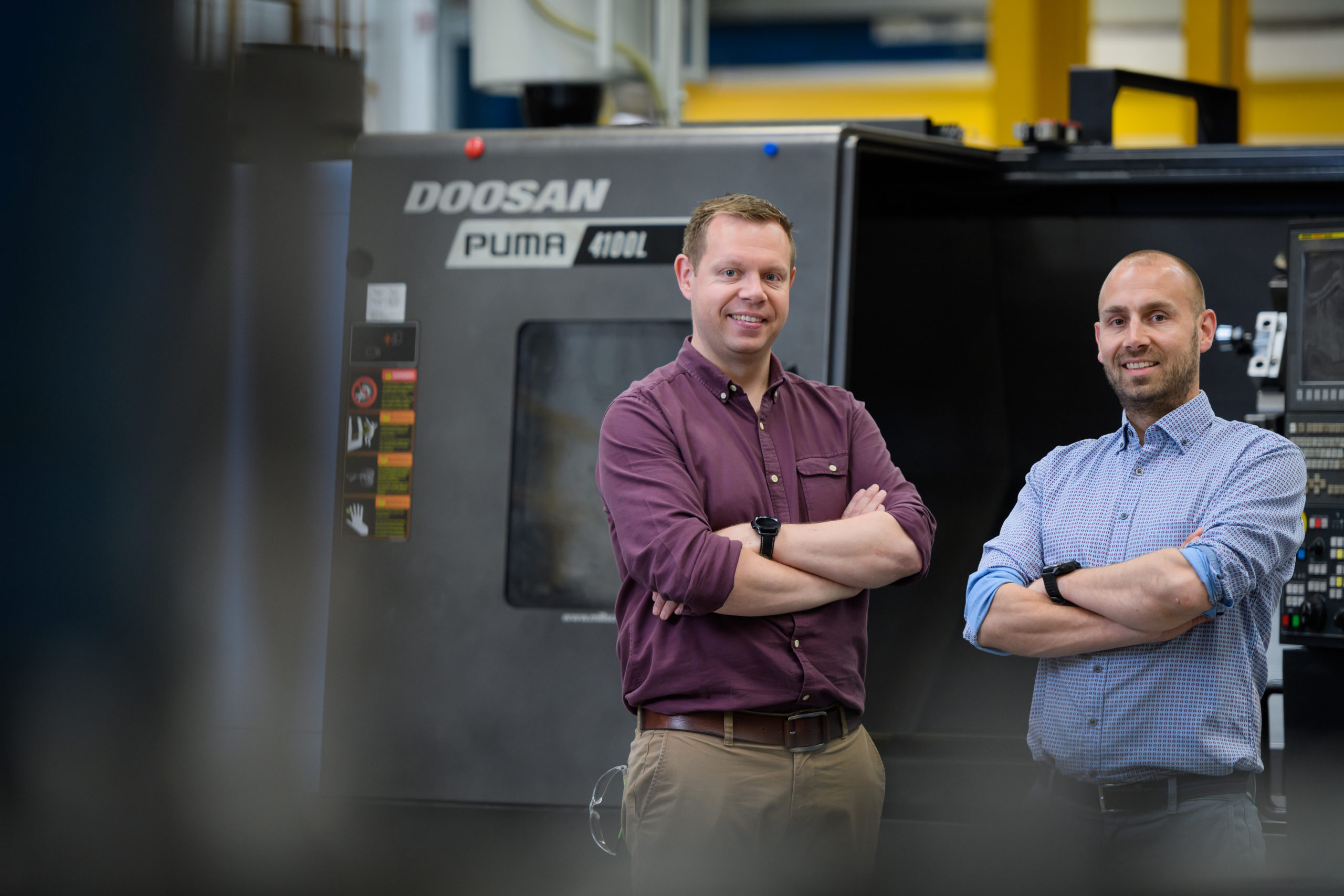

MNB Precision’s managing director, Luke Benton, explained how decades of experience in oil and gas has prepared the company for growth in rail. He said: “MNB was founded with the precise needs of the oil and gas market in mind and continues to serve this sector today. The tight tolerances and machining skill required to supply this industry have enabled us to diversify into other industries where safety is a priority, such as aerospace and rail.

“At this year’s Rail Live, we’ll be explaining just how precise our precision engineering capabilities are and looking to build further links with the industry to aid the development of future infrastructure.”

Thousands of rail professionals from across the UK are gearing up for Rail Live 2021, which takes place between June 16-17. Taking place at Quinton Rail Technology Centre in Long Marston, the event provides a focal point to make connections, discuss key topics, and explore the latest innovations. The show brings thousands of rail professionals together in a real railway environment and offers MNB the ideal platform to promote its capabilities to potential supply chain partners.

Following the cancellation of Rail Live 2020 due to the pandemic, this year’s event offers the chance for the sector to reconnect and work together to exploit the opportunities ahead. Rail will play a vital role in the UK’s economic recovery and green industrial revolution. In May, the Government announced £401 million of rail investment for projects including new stations, a Transpennine route upgrade and increased freight capacity between the Port of Southampton and the Midlands. This comes in the wake of the Chancellor’s Budget commitment to setting up of a UK Infrastructure Bank to support the delivery of key projects.

For the rail sector to upscale and provide a railway system fit for purpose, it must develop strong supply chains. That means tapping into the expertise of UK businesses such as MNB. The Government has set a target of spending a third of annual expenditure via SMEs by 2022 and events such as Rail Live help introduce the industry leaders to manufacturers with relevant expertise.

MNB has provided precision engineering solutions for four decades and has invested heavily in its 36,000 sq ft Coventry facility. The manufacturer has spent around £3.5m over the last four years, including £1.6m in the last few months, on state-of-the-art machinery and on the back of new servitized business model has developed a range of in-house capabilities, including Non-Destructive Testing, shot peening and spark eroding.

That commitment to innovation lies at the heart of the company’s incredible growth trajectory. Turnover increased by more than 500% in the three years up to February 2020, which led to MNB ranking 30th in the prestigious Sunday Times Virgin Atlantic Fast Track 100.

MNB can provide the rail sector with a one-stop-shop for precision engineering solutions right through from design consultancy and prototyping to bespoke products delivered to the customer’s door. To find out more about how MNB can help keep your rail project on track, visit stand M32, or find out more at www.mnbprecision.com