UK manufacturing business climbs up a gear with revolutionary prototype

A specialist UK precision engineering business has successfully produced the first of two prototypes that aim to revolutionise climbing safety gear all over the world.

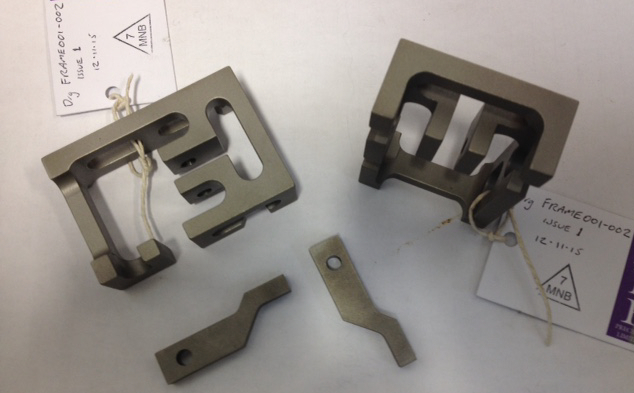

Midlands-based MNB Precision has been working with Estonian business Okill LCC to design and manufacture a prototype to bring an alternative take on an extraction climbing belt to global markets, under the Okill brand. While many market leading safety climbing belts tend to be bulky, distinctive, and difficult to fit onto some types of clothing, MNB and OKILL have successfully created a concept that brings multiple safety capabilities into a durable, optimal sized belt, with as few parts as possible. This will mean that climbers will not need to purchase specialist tactical uniforms in order to also wear a tactical climbing belt.

Inspired by the accessories worn by Peter Quinn in popular television drama series Homeland, the belt was been designed following a personal climbing experience by the MD of OKILL, Jorgen Post, who tied a rope from one river bank to another and then found that he could not pull himself over the rope with a standard uniform belt without the rope tearing under the weight. The new, lightweight design of the Okill product has been perfected by MNB Precision during the prototyping process over the last year and is now finally just a few months away from the first full assembly.

MNB was identified as one of few precision engineering businesses globally that has the capacity to both prototype the product in the early stages, and also manufacture the belt in mass volume once the product is launched commercially. The company’s high precision shot peening process was key in giving the belt a mat finish and the fact that the business specialises in both small, high precision milling, as well as larger projects, meant that MNB was prime for creating a multipart assembly with limited space.

For Jorgen Post, it is MNB’s location and reputation as a UK manufacturing business that makes it an ideal partner for the project. He commented: “The UK has a global reputation for quality manufacturing and it was clear from MNB’s list of clients that it is a flexible and professional business. We are working with a US business for the load bearing textile of the belt so it is easy to have parts shipped to the UK for mass production should this product take off.”

Luke Benton, Managing Director at MNB Precision, added: “We are fortunate that our business infrastructure allows us to take on interesting new projects such as this one and not only get involved at the prototyping stage, but also in mass production further down the line too. It’s been a challenging but exciting project to get this design and concept to the prototype stage and we are continuing to work closely with Okill to prepare it for assembly. This is a perfect example of the value that the UK manufacturing sector brings to the global engineering market.”

– Ends –

About MNB Precision

Established over 35 years ago, MNB Precision is a family run business based in Coventry, which provides manufacturing and precision engineering services to world leading companies across the oil and gas, power generation, rail, aerospace and other manufacturing industries. Specialising in precision engineering, the company’s 36,000 ft² factory offers services including CNC milling and turning, Jig Boring, Spark Erosion, Wire Erosion, Grinding and Shot Penning. These in-house capabilities are supplemented with a robust and controlled supply chain, enabling the business to offer an efficient turnkey solution to customers globally.

For further information, please contact:

Luke Benton, Managing Director, MNB Precision on Tel: 02476 696950, or John Edden, Bridge PR & Media Services on Tel: 024 7652 0025, or Email: john@bridgepr.co.uk